Health Impacts of Concrete Dust Exposure

Anyone familiar with the concrete cutting industry knows that dust is an ever-present companion. But just how harmful is this seemingly harmless powder? Well, as it turns out, not all dust is created equal, and concrete dust can carry its own set of health risks.

Concrete Dust: More than Meets the Eye

The production of concrete dust mainly arises during concrete cutting, concrete drilling, concrete grinding, or breaking. While it may seem minute, these fine particles can have deleterious health effects, especially when inhaled over long periods.

- Silicosis: One of the major components of concrete dust is crystalline silica. When inhaled over time, it can lead to a condition called silicosis – a scarring of the lung tissue. Silica dust can cause difficulties in breathing and may lead to other respiratory problems.

- Chronic Obstructive Pulmonary Disease (COPD): Constant exposure to concrete dust can increase the risk of developing COPD, a group of lung diseases that impede airflow.

- Lung Cancer: There’s growing evidence that links prolonged exposure to crystalline silica to an increased risk of lung cancer.

Different Types of Asphalt and Associated Risks

Not all asphalt is the same, and its use varies based on specific requirements. Two common types are:

- Hot Mix Asphalt: Typically used for roadways and is known for its durability. However, cutting this type can produce fumes that may lead to eye, nose, and throat irritation.

- Porous Asphalt: Frequently used in Avondale for its water-draining capabilities. When cut or broken, it tends to produce less fumes than the hot mix but can still generate harmful silica dust.

Cutting Through the Risks in Wairau Valley and Beyond

When cutting concrete, whether in Wairau Valley or anywhere else in Auckland, ensuring the safety of workers and those nearby is paramount.

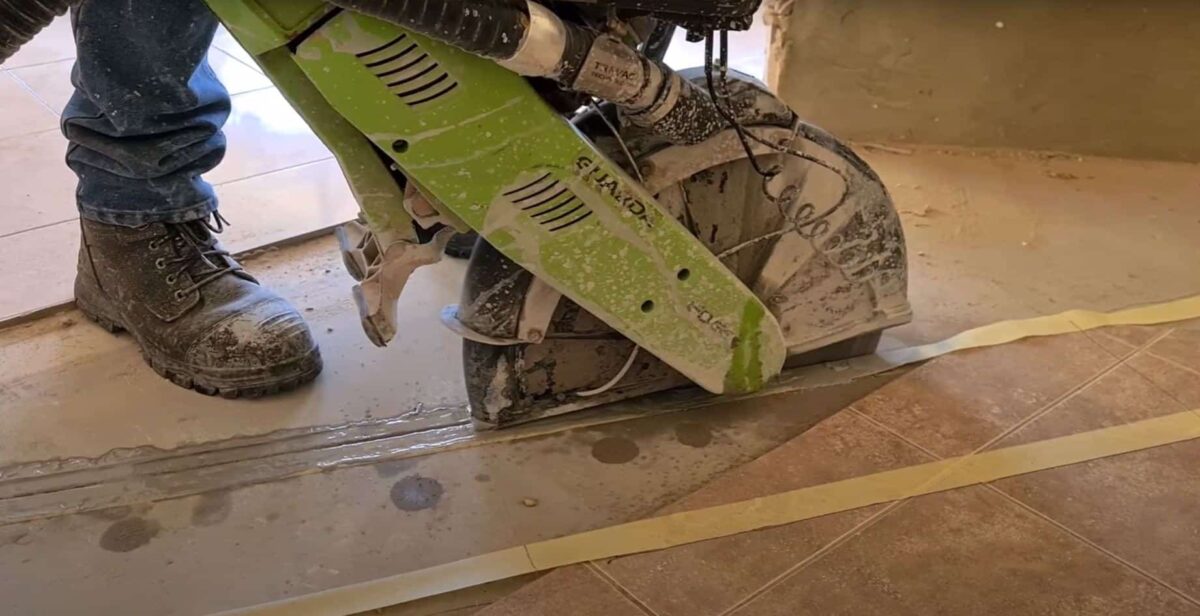

- Water Suppression: This technique involves using water to suppress the dust. The added benefit? It also keeps the saw blade cool, extending its lifespan.

- Local Exhaust Ventilation: This system captures and extracts the dust at the source, preventing it from dispersing into the air.

- Respiratory Protection: When other methods aren’t feasible, workers should wear respiratory protection to shield themselves from inhaling the hazardous particles.

Alternative Cutting Techniques: A Comparative Look

| Technique | Specifications | Scenarios |

| Dry Cutting | – No water used – Faster method | Quick jobs; short durations |

| Wet Cutting | – Water suppresses dust – Slower | Prolonged cutting; health priority |

| Diamond Cutting | – Precise cuts – Less dust produced | Intricate designs; indoor projects |

Engineering Innovations in Dust Management

In a bid to make concrete cutting processes less messy and hazardous, the industry is embracing innovative technologies. For instance, advanced filtration systems are being integrated into cutting tools, allowing for effective capture of minute particles. Additionally, researchers are continuously exploring materials and coatings that produce less dust when cut.

Ensuring Safe and Effective Concrete Cutting in Auckland

Concrete Cutting Auckland is acutely aware of the risks and is committed to using industry best practices and cutting-edge technology to minimise dust exposure. Our commitment to safety and expertise in handling diverse concrete cutting requirements makes us the go-to choice for all your concrete needs. Remember, health and safety aren’t just regulations – they’re imperatives for safeguarding our most valuable asset: our people.

Understanding Concrete Cutting: Frequently Asked Questions

What is the primary concern with concrete dust exposure?

Prolonged exposure to concrete dust, particularly the crystalline silica it contains, can lead to several respiratory conditions like silicosis, chronic obstructive pulmonary disease (COPD), and even lung cancer.

How can workers reduce the risk of inhaling concrete dust?

Implementing safety measures such as water suppression, using local exhaust ventilation systems, and wearing respiratory protection can significantly reduce the risk of inhaling harmful dust particles.

Why are there different types of asphalt?

Different types of asphalt cater to varied requirements. For instance, Hot Mix Asphalt is durable and primarily used for roadways, while Porous Asphalt, commonly seen in places like Avondale, offers water-draining capabilities.

How does wet cutting differ from dry cutting?

Wet cutting involves the use of water to suppress dust and cool the saw blade, making it a slower but safer method. In contrast, dry cutting is faster but doesn’t employ water, leading to more dust production.

Are there innovations in the concrete cutting industry for better dust management?

Yes, the industry is continuously adopting advanced technologies. One notable innovation is the integration of sophisticated filtration systems into cutting tools, capturing even the minutest of dust particles effectively.

Why should I choose Concrete Cutting Auckland for my concrete needs?

The concrete cutters at Concrete Cutting Auckland are committed to industry best practices, utilising cutting-edge technology to ensure both the safety of its workers and the quality of its work. Our focus on health, safety, and expertise makes us the preferred choice for diverse concrete cutting requirements in the region.